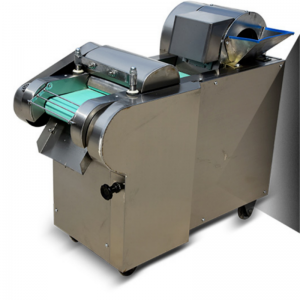

Features:

Novel design, simple operation, convenient installation and maintenance, high efficiency, good sealing, stable performance and high production efficiency.

Qingdao Kahe Intelligent Equipment Co., Ltd. specializes in providing automatic production line equipment for chili sauce, from raw material processing to frying, transfer, filling, vacuum capping, labeling, coding, plastic sealing, packing and storage. The main features of this production line are as follows:

The whole process of the production line from raw material processing to final packing and warehousing is automated flow operation, which has changed the traditional workshop processing mode;

The production line is highly automated, greatly improving labor efficiency, requiring less labor and increasing output Large, to prevent the loss of sauce, reduce production costs.

The production line is a closed operation, which prevents secondary pollution and ensures food safety and sanitation. The production workshop is clean and beautiful, which meets the requirements of modern food.

Operators can start work after simple training, and personnel replacement will not easily affect product quality.

Its core equipment, the automatic frying pan, has a variety of heating methods to choose from. The stirring method is unique, and the sauce is mixed evenly without sticking to the pan. It has a high degree of automation and can meet the strict process requirements of customers.

The cooling effect of the sauce is good, which ensures the requirement of homogeneous and constant temperature of the material in the packaging process, and effectively reduces the error in the measurement of the material packaging.

The material conveying pipes are all made of sanitary grade stainless steel fittings, which are clean and hygienic and easy to clean. The conveying system adopts stainless steel special sauce pump, which runs stably and ensures the original state of the sauce.

The filling production line is provided by professional manufacturers in the industry, and the whole process of unscrambling, washing, filling and packing is automated and continuous.

The core components adopt international famous brands, PLC and touch screen from Siemens or Panasonic, electrical appliances from Schneider, cylinder from SMC, photoelectric from Omron ensure the smooth operation of the production line.